Paper pulp packaging has grown to be a core concentrate for corporations worldwide as they shift from unsustainable supplies towards eco-welcoming methods. Molded pulp packaging offers a sustainable and cost-helpful way to make high-quality packaging that may be customizable and biodegradable. 1 region driving innovation may be the introduction of high-performance pulp molding click here equipment, similar to the Dwellpac Semi-Hotpress device. These equipment assist organizations streamline generation even though ensuring precision and trustworthiness.This information will explore The real key features of large-performance pulp molding equipment, upkeep tips for long-expression utilization, approaches to chop fees whilst maximizing output, and how automation improves output and high-quality. no matter whether you might be a company operator or possibly a packaging Experienced, you can attain precious insights that can help enhance your manufacturing procedure.

Table of contents:

crucial Features of significant-effectiveness Pulp Molding devices

Maintenance guidelines for extended-time period equipment functionality

Cost-conserving Strategies in manufacturing

How Automation enhances Output and high-quality

Key capabilities of substantial-Efficiency Pulp Molding devices

High-efficiency pulp molding equipment are revolutionizing how molded pulp brands work. The Dwellpac Semi-Hotpress equipment is just one these kinds of example. It stands out for its State-of-the-art Regulate process, large clamping accuracy, and seamless hydraulic general performance. With options like precision shaping and eco-welcoming mold pressing technological innovation, it makes sure that each eco-pleasant box packaging products is consistent in high quality and durability. This is significant for industries needing tailored alternatives like foods packaging, electronics, and industrial elements. these types of machines also assist An array of custom molded pulp packaging wants, featuring important flexibility in generation.

upkeep strategies for prolonged-Term Machine general performance

protecting a pulp molding device is significant to ensuring constant output and maximizing its lifespan. common maintenance tasks involve cleansing the molding surfaces, inspecting hydraulic programs for use and tear, and guaranteeing the Command procedure is up to date for peak general performance. The Dwellpac machine is meant to simplify these processes, letting molded pulp companies to streamline upkeep. normal inspections and proactive care don't just minimize unexpected breakdowns but also enable preserve the precision standards needed for higher-top quality paper pulp packaging.

Expense-Saving methods in generation

Price-performance is a primary concern for molded pulp companies. To save costs even though sustaining good quality, they're able to optimize materials utilization by leveraging effective pulp mold pressing technologies to attenuate squander, put money into Electricity-economical equipment such as Dwellpac Semi-Hotpress Machine to scale back energy intake, and educate staff to fully employ Highly developed equipment to prevent glitches that result in inconsistencies or wastage. Additionally, buying eco-helpful components in bulk may help take full advantage of decreased charges and minimize Over-all generation charges. By adopting these strategies, brands can stay competitive while providing higher-high quality, custom made eco-friendly packaging to purchasers.

How Automation Improves Output and top quality

Automation is now a pivotal aspect of modern manufacturing procedures. Superior pulp molding machine companies, such as Dwellpac, combine automation to enhance operational efficiency. Automated techniques, by together with attributes like intuitive Handle panels and genuine-time precision checking, decrease the likelihood of human mistakes. This makes certain that each individual mold created meets strict excellent benchmarks. With automation, corporations can also handle massive-scale generation runs a lot more efficiently, Assembly precise deadlines when making molded fiber packaging at competitive premiums. Furthermore, the dependable quality attained by means of automation reinforces shopper trust in eco-welcoming packaging answers.

High-performance pulp molding equipment are enabling organizations to satisfy increasing demand for sustainable packaging options. By buying Superior systems, corporations can create tailor-made molded paper pulp products which don't just safeguard the ecosystem but will also offer top-quality performance and sturdiness. With innovative machines and thoughtful servicing methods, firms can triumph over manufacturing problems, cut down operational expenditures, and give eco-welcoming products which cater to world wide sustainability ambitions.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Rick Moranis Then & Now!

Rick Moranis Then & Now! Alisan Porter Then & Now!

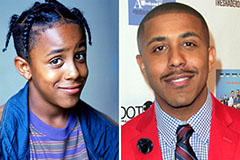

Alisan Porter Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!